What does VFT® provide for the User?

VFT is a computer-based software suite that allows designers to predict potential weld-induced distortion and residual stress states based on a planned fabrication process so that weld design strategies can be implemented to significantly reduce or eliminate these undesirable states prior to fabrication.

How does a product designer implement VFT®?

The user needs to provide information describing

the structure to be welded:

the structure to be welded:

- Structure Geometry

- Weld Type

- Weld Material Properties

- Torch Speed

- Structure Material Properties

- Number of Weld Passes

The solid model developed by the user through standard CAE/CAD packages will have a Finite Element (FE) mesh generated for the simulation.

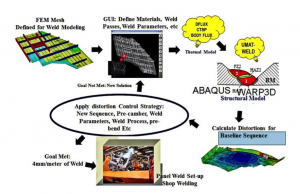

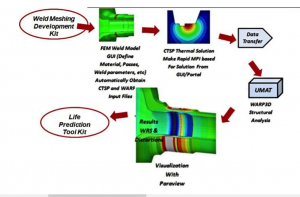

This FE Mesh, along with the properties described above, will be input through the solution process via a graphical user interface (GUI). (Figures on the right illustrate VFT® process flow)

What does the product designer receive from VFT®?

The output from the VFT® analysis includes predicted distortion values (deformations) of the structure and residual stresses due to welding. These results are provided in graphical format (contour and fringe plots) and tabular values at selected locations on the structure.

This type of information permits the designer to employ control strategies (e.g. weld sequencing and clamping) to reduce or eliminate distortions and residual stress states induced by welding, which ultimately leads to longer design life for the final product. Furthermore, the weld residual stresses can be used to enhance fatigue and stress corrosion cracking predictions.

This type of information permits the designer to employ control strategies (e.g. weld sequencing and clamping) to reduce or eliminate distortions and residual stress states induced by welding, which ultimately leads to longer design life for the final product. Furthermore, the weld residual stresses can be used to enhance fatigue and stress corrosion cracking predictions.

The main focus of VFT® is the use of modeling and simulation methodologies to enhance fabrication processes resulting in improved product performance, better product quality, less maintenance,improved warrantability, and lower cost.

Through a more recent US DOE Small Business Innovative Research (SBIR) program, Engineering Mechanics Corporation of Columbus, (Emc2), has adapted VFT® so that small- and medium-size enterprises (SME) can have cost effective access to the tool to improve their products and realize the full benefits of its use.

Prior to this SBIR effort, VFT® had been out of the reach of most SMEs because of the need for high end expensive computational resources and highly trained and experienced staff. Emc2’s modifications now provide SMEs with a readily available tool via the high performance computing (HPC) facility at the Ohio Supercomputer Center (OSC) within the Ohio State University (OSU), which is easy to use and low cost.

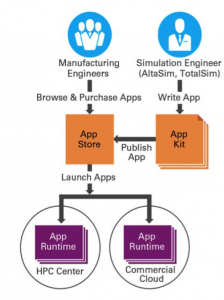

At OSC, VFT® is found on the AweSim website making it simple for SMEs to seamlessly and securely access all modules of VFT®. AweSim is an OSC program to help lower barriers to entry for HPC- based modeling and simulation (M&S) especially for SMEs. It acts as the equivalent HPC version of various ‘App Stores’ that exist for Smartphone platforms and employ a userfriendly, tailored format for a diverse set of end users at affordable prices. Three main AweSim components have been developed for user access: App Kit for building apps; App Runtime for running apps; and App Store for locating and buying apps (See Figure on the right). Additionally, a range of training options is offered.

Through a more recent US DOE Small Business Innovative Research (SBIR) program, Engineering Mechanics Corporation of Columbus, (Emc2), has adapted VFT® so that small- and medium-size enterprises (SME) can have cost effective access to the tool to improve their products and realize the full benefits of its use.

Prior to this SBIR effort, VFT® had been out of the reach of most SMEs because of the need for high end expensive computational resources and highly trained and experienced staff. Emc2’s modifications now provide SMEs with a readily available tool via the high performance computing (HPC) facility at the Ohio Supercomputer Center (OSC) within the Ohio State University (OSU), which is easy to use and low cost.

At OSC, VFT® is found on the AweSim website making it simple for SMEs to seamlessly and securely access all modules of VFT®. AweSim is an OSC program to help lower barriers to entry for HPC- based modeling and simulation (M&S) especially for SMEs. It acts as the equivalent HPC version of various ‘App Stores’ that exist for Smartphone platforms and employ a userfriendly, tailored format for a diverse set of end users at affordable prices. Three main AweSim components have been developed for user access: App Kit for building apps; App Runtime for running apps; and App Store for locating and buying apps (See Figure on the right). Additionally, a range of training options is offered.

Other Attributes

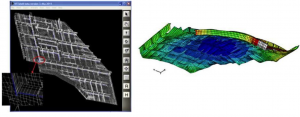

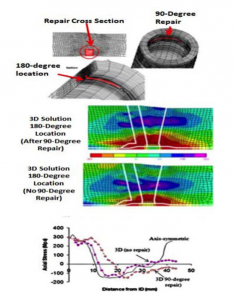

VFT® is not only useful in reducing/eliminating distortion and residual stress states due to welding processes, but is also used to establish more optimal strategies for weld repairs. For example, in pipe-type structures a defect may only be part way around the circumference, so only a partial repair would be necessary. (the figure on the right shows examples of repair analyses).