In 1904, Charpy published a paper in the journal “Mémoires de la société des ingénieurs civils de France ». This paper improved on the test developed by S.B. Russel in the beginning of the 20th century and became a reference in term of metal testing. We provide you below a translation of the introduction of the original paper (available in french in the references below) as well as some schematics and photos of the original Charpy machine (found in the other references listed at the end of this page).

In 1901, we have described in a note the testing of metals by bending notched bars via impact loading, and presented the results to the “Société des Ingénieurs Civils” and at the Conference for the International Association on Material testing in Budapest. Since then, we have pursued the study, focusing on the controversial as well as the aspects ignored by the numerous studies published on the subject. The present paper aims to describe the new experiments performed since. Most of them have been verbally described during the meetings of the French Section of the International Association on Materials Testing.

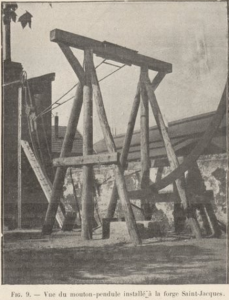

At the end of the 1901 paper, we considered the use of repeated impact loadings with an ordinary striker (“mouton ordinaire”) as sufficient for a first set of practical tests. It has the great advantage to use equipment available in all workshops and not requiring the purchase of any expensive equipment for which no operational procedure has yet been finalized.

This procedure has been vividly criticized. We think however it is important to point out that it was been used for several experiments with favorable results and outcomes. The French Navy has used it for three years to study armor plating: all the tests were performed without any issues. Furthermore, in the April 1902 issue of “Engineering”, we can find the description of the experiments carried out by Yarrow et al. on metals used in boilers: notched bars were exposed to repeated impacts loads from a 4kg striker dropped from a height of 45 cm. The conclusion of the article is:

” For the immediate goal of this study, i.e. the comparative merits of the steels considered, the approach followed by Yarrow et al. gave complete satisfaction. Careful experiments have shown that it efficiently assessed the brittleness of metals”

Nevertheless, for very precise measurements or for the scientific study of brittleness, a numerical approach to estimate the fracture work is preferable

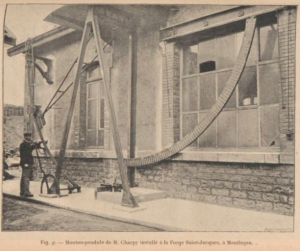

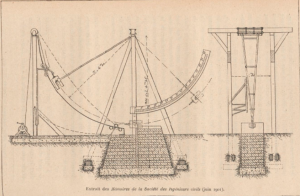

The pendulum drop weight described in 1901 has been proven to be satisfactory for the above task, withstanding continuous testing for several years.

We have been working into perfecting the machine and develop versions less cumbersome than the original one…

It is possible to vary indefinitely dimensions and designs of such machines. After consideration of a large number of designs, we settled on two specifics (one large and one small) which seem to cover of most of the test cases.

Source:

original paper (in French)

publication of M. Charpy work in “Le genie Civil” journal

publication of M. Charpy work in “La revue d’Artillerie” journal